Why OEM Cosmetic Manufacturing is Revolutionizing the Beauty Industry

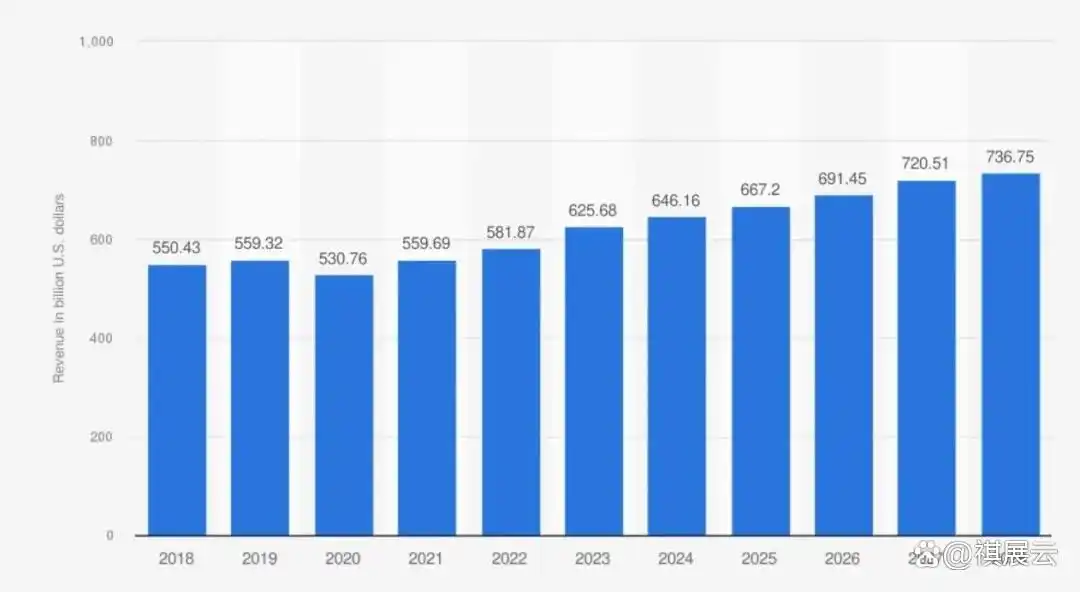

The global cosmetics market is projected to reach $463.5 billion by 2027 (Statista), with private label skincare brands driving 30% of this growth. For entrepreneurs and startups, OEM cosmetic manufacturing has become the gateway to launching a brand without massive upfront costs. Whether you’re a solo founder or a business scaling globally, partnering with a certified OEM/ODM cosmetics factory lets you focus on branding while experts handle production.

How OEM Cosmetic Manufacturing Works: A 5-Step Process

- Brand Order & Agreement

- The brand owner (formerly VAR) submits specifications: formula, packaging design, and MOQ (Minimum Order Quantity).

- Confidentiality agreements ensure IP protection for custom formulations.

- R&D & Compliance Checks

- OEM labs develop samples adhering to ISO 22716 (GMP) and regional regulations (e.g., FDA, EU Cosmetics Regulation).

- Production & Quality Control

- Raw materials are sourced from vetted suppliers (e.g., Halal-certified ingredients for Muslim markets).

Batch testing ensures stability in viscosity, pH, and microbial safety.

- Raw materials are sourced from vetted suppliers (e.g., Halal-certified ingredients for Muslim markets).

- Private Label Packaging

- Options include eco-friendly packaging (recyclable tubes, biodegradable jars) or luxury finishes (gold foil, embossing).

- Global Logistics & Distribution

- OEMs often provide white-glove shipping services, handling customs clearance for cross-border sales.

How to Choose the Best OEM Cosmetic Manufacturer: 7 Critical Factors

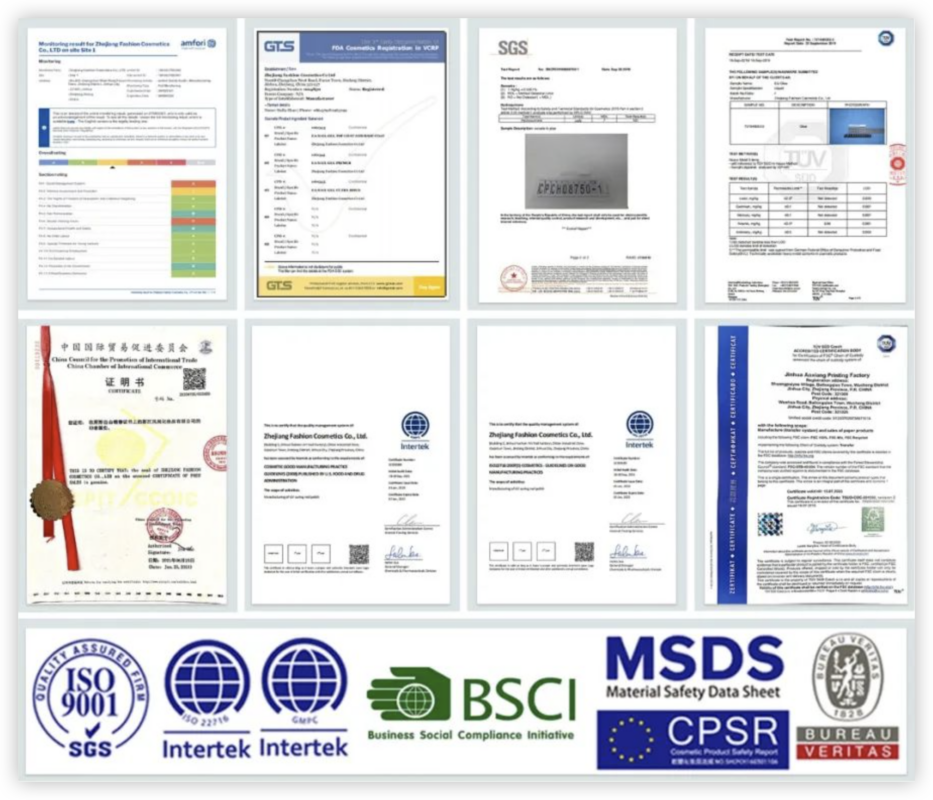

✅ Certifications & Compliance

- Must-have: ISO 22716 (GMP for Cosmetics), ISO 9001, and FDA/EU compliance.

- Bonus: Vegan, Cruelty-Free, or Halal/Kosher certifications for niche markets.

✅ R&D Capabilities

- Look for labs with 3D skin modeling technology or expertise in trending formulations (e.g., blue light protection serums, probiotic skincare).

✅ Minimum Order Quantity (MOQ)

- Start small: Many OEMs offer low MOQ private label cosmetics (500-1,000 units) for startups.

✅ Packaging Customization

- Request sustainability audits for materials (e.g., FSC-certified paper, PCR plastic).

✅ Delivery Timelines

- Average lead time: 8-12 weeks for custom skincare manufacturing (from formula to finished goods).

✅ Legal Safeguards

- Contracts must cover IP ownership, exclusivity clauses, and penalty terms for delays.

✅ Cost Transparency

- Break down fees: Formula development (2k−10k), tooling (mold costs), and per-unit pricing.

Proven Benefits of OEM Cosmetic Manufacturing for Brands

🔥 Cost Savings Up to 70%

- Avoid 10M+factorysetups.OEMsleverageeconomiesofscal**e–produce∗∗privatelabelmoisturi**zers∗∗a**t1.50/unit vs. $5+ in-house.

💡 Speed to Market

- Launch products in 90 days vs. 18+ months with in-house R&D.

📦 End-to-End Solutions

- Top OEMs handle product registration (e.g., China’s NMPA filing, EU CPNP), clinical trials, and even Amazon FBA prep.

🌱 Sustainability Edge

- Partner with green cosmetic manufacturers offering carbon-neutral production and refillable packaging designs.

🔒 IP Protection

- Full ownership of patented formulations and trademarked packaging.

📈 Scalability

- Start with 500 units, scale to 50,000+ as demand grows – no inventory risks.

FAQ: OEM Cosmetic Manufacturing Explained

❓ “Can I customize formulas for sensitive skin?”

- Yes! OEMs offer hypoallergenic formulations with COSMOS-certified organic ingredients.

❓ “What’s the MOQ for private label cosmetics?”

- Typically 500-1,000 units for skincare, lower for luxury makeup OEM services.

❓ “How to ensure quality control remotely?”

- Reputable OEMs provide live production tracking and third-party lab reports (SGS, Intertek).